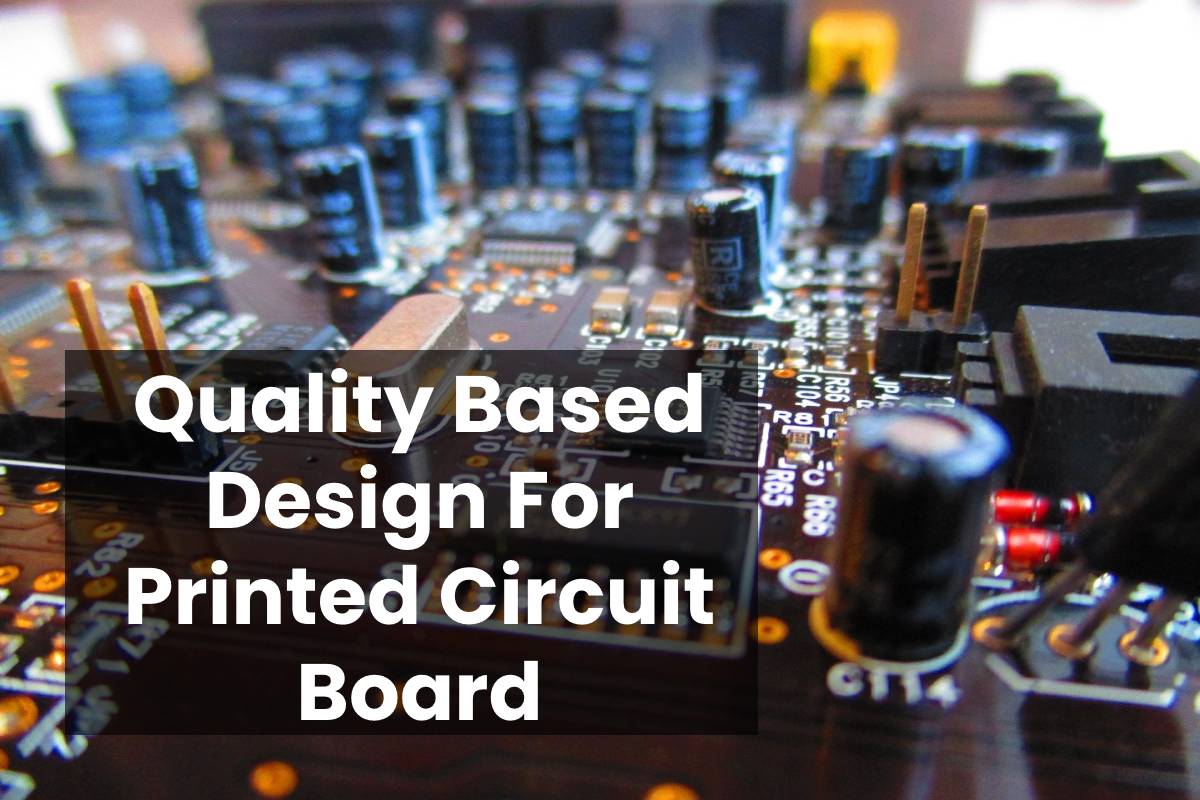

PCB Design Excellence: Optimizing Quality Every Step

What’s a PCB and Why It’s the Heartbeat of Electronics

Think of a Printed Circuit Board (PCB) as the shopping list for a gadget—only the list is made of copper, glass, and a sprinkle of creativity. It’s the backbone that lets resistors, capacitors, and so many tiny parts have a conversation without shouting.

Meet the Cast of Tiny Stars

- Resistors keep the flow in check, like a traffic cop for electrons.

- Inductors – the magnet‑magicians that store magnetic energy.

- Capacitors store electric vibes—think of them as batteries for a one‑shot party.

- And countless others that are the unsung heroes of every modern device.

The Shield That Keeps the Fires at Bay: FR‑4

FR‑4 is the superhero in your PCB wardrobe. It’s a Fire Retardant glass‑fiber epoxy, designed to chill the flames before they can spread. Here’s why it’s the go‑to material:

- High glass‑transition temperature — can handle the heat like a sauna‑loving yogi.

- Reliable arc resistance and dielectric breakdown thresholds.

- Sturdy flexural strength, meaning it doesn’t buckle under stress.

- Built‑in solder mask that keeps unwanted connections from sneaking in.

- Can withstand a warm cuddle up to 120–130 °C depending on thickness.

Why not pick the cheaper FR‑1, FR‑2, or the moisture‑prone FR‑3? Because quality demands six to eight layers of FR‑4. That translates to a crystal‑clear, glassy state that’s tougher than a polystyrene superhero’s costume.

Capacitors: The Party‑Planners of the PCB

Capacitors are the main event hosts on a PCB. They gather and release electric energy smoothly. Think of them as the DJ that keeps the frequency bumps from being a full‑blown nightmare.

Quick TL;DR Review

- PCBs are the communication highways in gadgets.

- FR‑4 is the gold standard for heat resistance and structural integrity.

- Capacitors are essential for energy storage and frequency stability.

So next time you tap your phone or crank up a laptop, remember the tiny circuit that keeps everything humming—thanks to clever design and a bit of FR‑4 wizardry!

Successful FR 4 material general properties are as follows:-

High glass transition temperature:-

Frost‑Fighting FR4: It’s Cool, It’s Stubborn, It Breathes Easy

When you think about a material that’s both silky smooth and tough enough to roll around all day, FR4 steps into the spotlight. This guy doesn’t just melt at any temperature – it stays chill and stubbornly keeps its shape no matter how hot the world gets.

Why FR4 is the Star of the Show

- Melting Temperature? Low. That means it won’t turn into a gooey mess just because someone left a mug of coffee on it.

- Moisture and Muck? No Way. FR4’s resistant to water and those pesky pollutants – it’s essentially a champion of “dry” environments.

- Shape Integrity. Even when conditions shift, FR4 keeps its geometry intact, making it a real lifesaver in the manufacturing arena.

Bottom‑Line Takeaway

It’s not just another board; FR4 is the “brick that won’t crack.” Thanks to its low melting point and winning resistance, it’s a favourite for engineers who can’t stand the idea of their work evaporating under heat. Keep it cool, keep it solid – that’s the FR4 promise.

Arc resistance:-

What’s the Deal with Arc Resistance?

Arc resistance is all about how well a plastic can keep its composure when a high‑voltage electrical spark tries to wreak havoc. Think of it as the plastic’s personal bodyguard against a flashing, high‑powered fire‑starter.

Why Count on It?

- Safety First: It keeps things from turning into a tiny fireworks show on your gadget.

- Longevity: The stronger the arc resistance, the longer your device can live without a sudden “abracadabra.”

- Reliability: Devices with high arc resistance run smoother, just like a coffee machine that never gets a burnt red alarm.

A Quick Real‑World Example

Picture a tablet that’s on the go. If it’s made from a plastic with solid arc resistance, a stray lightning strike won’t turn it into a smoky relic—rather, it will keep humming along, saving your battery and your sanity.

Bottom Line

If you want your plastic stuff to put on its own “arc‑proof” cape, make sure it’s built with high arc resistance. That way, even the most dramatic sparks can’t bring it down.

Dielectric breakdown:-

The Day a Dielectric Goes MIA

Ever wondered what happens when your insulating “guard” suddenly decides to take a holiday? That poorly-timed holiday is what engineers call a deterioration of insulation – basically the moment your material lets the electric current slip through like a mischievous ninja.

Why It Happens

- Electric Stress Overload: Like a marathon runner hitting the wall, too much voltage makes the insulating barrier sag and crumble.

- Magnetic Show‑off: In some battlefields, a magnetic field can act like the sneaky spoiler that loosens the material’s grip.

- Temperature Woes: Heat turns the once‑stalwart shield into a melting, wobbly pasta.

All Aboard the Breakdown Express

When the failure kicks in, the insulator is appalled – it no longer blocks the current pathway, turning a quiet circuit into a roaring fire. Engineers warn: this is the signal to either boost the material or patch the board before the fire department gets involved.

Dielectric constant:-

Understanding Energy in Electric Fields

What’s the deal with dielectric materials?

When an electric field swirls around a material, that material can pack a punch of energy inside it. The amount of “electric potential energy” you can stash in the material is all about its dielectric constant—the same number that tells you how well an insulator can handle that electric buzz.

In Plain English

- Imagine a sponge that’s super good at holding water. The sponge’s ability to hold water is like the dielectric constant of a material holding electric charge.

- The higher the dielectric constant, the more electric energy the material can store.

- Think of it like a battery made out of insulation—more charge, more potential.

Why It Matters

- Capacitors: They’re basically “energy reservoirs.” Their performance links directly to the dielectric constant of the insulating material between the plates.

- Engineering: Designing everything from headphones to power grids depends on choosing the right dielectric constant.

Quick Takeaway

Dielectric constant isn’t just a number on a form. It’s the secret sauce that lets electric fields stash energy in materials—think of it as the material’s “energy‑banking” power.

Dissipation factor:-

The Hidden Language of PCB Materials

Why the Details Matter

Engineers often think material choice is just a high‑level decision, but the nitty‑gritty specs are the real MVPs—often slipping under the radar. Those little numbers actually tell you how the board will perform, like the secret handshake of electronic efficiency. They’re sometimes called loss tangent in fancy circles, but we’ll keep it simple.

-

Loss Tangent: The Energy Drag

It measures how much power the board “suck’s” away. Low loss = smooth sailing.

-

Thermal Stability: Keeping Cool Under Pressure

Baber that keeps your layers from fusing like a bad relationship.

-

Dielectric Constant: The Speed Factor

Higher values can speed up signals, but watch out for signal integrity.

-

Happy Circuits, Happy Life

Skipping these bars often turns a high‑speed dream into a low‑speed nightmare.

So next time you’re brainstorming board material choices, remember: delve into those parameters—they’re not just dots on a sheet, they’re the heartbeat of your circuitry.

High decomposition temperature:-

Decomposing Compounds: Heat‑Resistant Bonding Explained

Short‑take: When you heat stuff up, most metal compounds start to break apart like a shaken soda, but the strong bonds inside still stubbornly hold on.

Why Heat Makes the Break‑up Easy

- High temperatures give atoms the energy they need to shake off their partners – rapid decomposition is the rule.

- Metals that sit low on the reactivity ladder (think zinc and barium) are the easiest to get fizzing – they’re already weak on the inhibitory front.

- Conversely, stronger, “tight‑knit” bonds require more force to rip apart, so they stay put even when the furnace is roaring.

Bottom‑Shelf Metals in Action

When those less reactive metals reach a high decomposition temperature, you’ll notice their compounds start to disintegrate almost instantly. It’s basically a chemical pop‑culture moment – the compounds are splitting faster than a viral meme spreads.

Bottom Line

Heat is the ultimate party trick for breakable compounds, but if the bonds are too strong, they’ll wait until you bring the heat to the next level. So, watch your metals and keep your temperature logged!

Flexural strength:-

Bend Strength: The Ultimate Test of a Material’s Panache

Picture a steel ribbon sawing through a force of nature. That last moment before it gives up—when it cracks or snaps—marks the very edge of its resilience. Scientists call that the bend strength, the stress a material can endure right before it yields in a flexure test.

Why It Matters

- Real‑world Grip – Imagine bending a ruler until it snaps. That snap point is the material’s maximum bending stress.

- Design Stakes – Engineers use bend strength to decide whether a component can survive the daily stresses of trucks, bridges, or even your coffee mug.

- R&D Intelligence – A higher bend strength means a sturdier, more versatile alloy or polymer—ready for the next big innovation.

Getting the Numbers

In a flexure test, the sample is clamped at two ends, and a load is applied at the centre. The diagram below shows the calculation (no fancy equations, just the gist):

Stress = Force / (Moment Arm × Cross‑Section Area)

When the stress peaks—just before the momentary break—scientists record that vale as the material’s bend strength.

Humorous Take

- “If your bookshelf could talk, it’d brag about its bend strength, saying, ‘I only snap under giant snowmen!’”

- “Cake lovers, beware: the biscuit that bends before it breaks is not your safe dietary choice.”

- “In the world of materials, the bend strength is like the last dance before the disco lights go out.”

Final Thought

Think of bend strength as the “final score” in a material’s endurance game. It tells us how much love a material can stand before it’s time to upgrade. Rough or silky, sturdy or fragile—the numbers matter all the same. So next time you’re bending something, keep an eye out for that crucial snap point—it’s the ultimate indicator of toughness.

Solder mask:-

Meet the PCB’s Solid‑Blue Sidekick

Picture the PCB as a silent superhero wearing a cape on both its top and bottom. That cape? It’s the protective layer that shields the circuitry from splashes, dust, and the occasional accidental coffee spill.

Why 1.6 mm is the Go‑To Choice

In our industry the one‑size‑fits‑all answer is a 1.6 mm thick woven fiberglass laminate. Think of it like the trusty canvas on a canvas painting—sturdy, reliable, and just the right thickness to keep everything together.

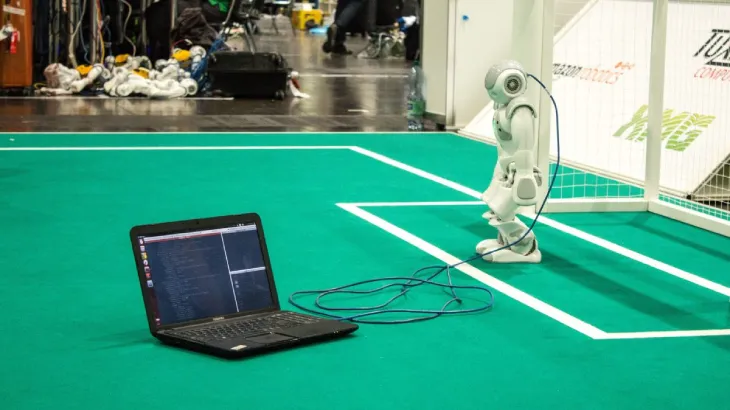

How to Build a Quality PCB: The Playbook

- Start With Smart Data – Hand the right numbers to the right tools.

- Chose the Right Equipment – Don’t plug a paper shredder into a PCB machine.

- Buy the Right Materials – Buying top‑grade stuff saves you from future headaches.

- Design The Best Process – A well‑planned workflow is like having a GPS for complex engineering.

- Hire the Right Operators – Skilled hands and a bit of grit can turn a simple board into a masterpiece.

When all these steps line up, the result is a PCB that looks like it was made by a seasoned craftsperson—sharp, precise, and wrapped in FR 4 goodness. Those trained operators? They’re the ones who transform a plain board into a high‑profile wonder. Their hard work and expertise are the secret sauce—making every circuit feel like it’s been polished by a wizard.

Bottom Line: The Power of the Right Team

Every PCB can be a hero, but only when it’s backed by the right data, gear, material, process, and people. Get these ingredients right, and you’ll see a board that not only performs but also whispers a little thank‑you to the engineers who built it.