Mastering Additive Manufacturing: 5 Essential Design Hacks

Cracking the Code of Additive Manufacturing: 5 Tips That Will Keep You Ahead of the Curve

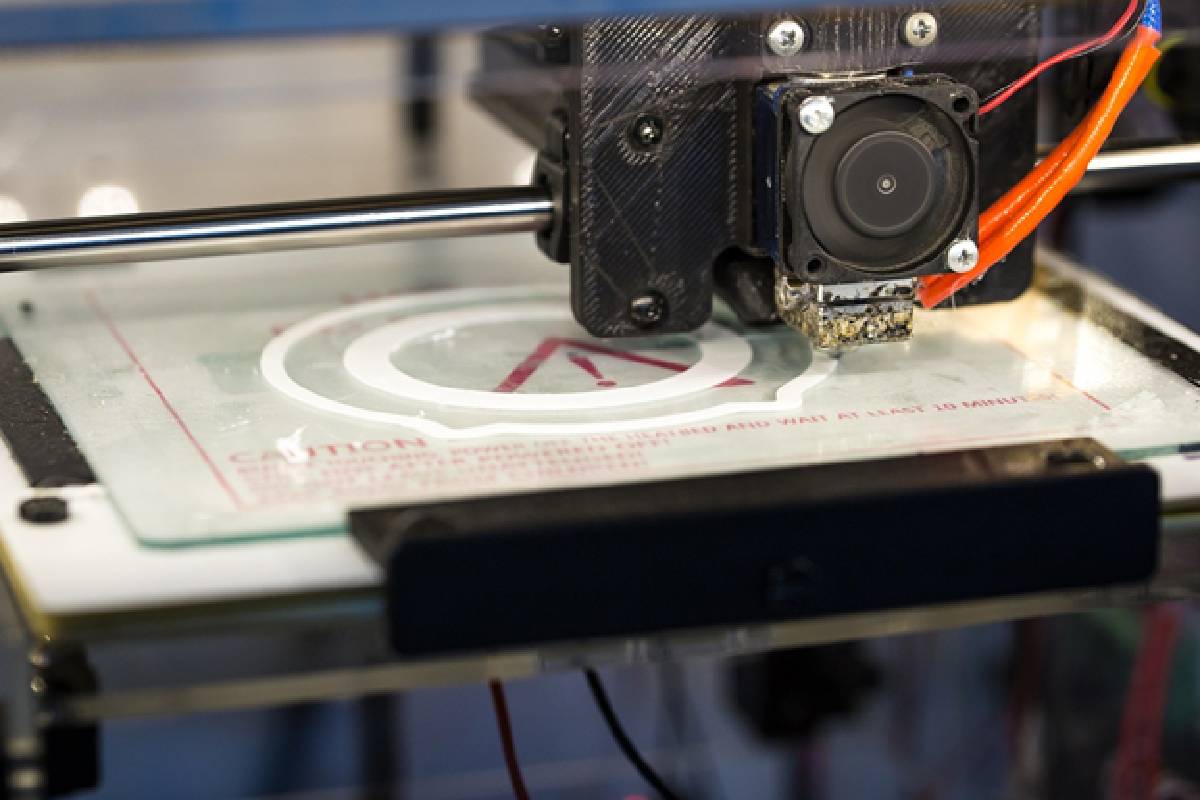

Let’s be honest: the popularity of 3D printing is no mystery. Wildly accessible design software, a surge in tech‑savvy creators, and the sheer thrill of bringing a model to life from nothing are forces that have turned additive manufacturing into a cultural phenomenon. Yet, despite all the buzz, many users still hit the same rookie pitfalls that can wreck an otherwise brilliant build. Below are five quick wins (and a touch of humor) that’ll help you dod Gis the design blunders that throttle your final product.

-

1. Embrace the Freedom

Think of your printer as a sandbox with endless possibilities. Don’t stick to rigid rules—let your imagination roam. If you’re comfortable, experiment with unconventional geometries or materials. Just remember: the more “creative,” the greater the risk of a final shape that looks less like a masterpiece and more like a confetti disaster.

-

2. Don’t Fear Parallelization

Running multiple jobs at once can feel like juggling flaming swords, but it’s a whole lot cheaper than salvaging a single build. Pair up your prints, and watch your efficiency skyrocket. The trick? Keep each job properly spaced to avoid thermal stress creeping in. Parallel printing is no risk‑free, but done right, it’s your secret weapon.

-

3. Pay Special Attention to Deposition Time

Check the “time” annotations—or if none exist, the manual quick‑look. Long deposition times can lead to warping or even print collapse. Keep an eye on the clock and tweak your layer thickness or build speed accordingly. A well‑timed print is the difference between a smooth finish and a board‑full of cracks.

-

4. Trust in Data‑Based Scheduling

Manual schedules are ultra‑time‑consuming and often overlook hidden intricacies. Let your printer’s software do the heavy lifting: it’ll analyze your design, determine the most efficient orientation, and suggest the best process parameters. The data‑driven approach is not “macro magic” but a reliable shortcut—use it, and you won’t be doing the same old cycles again.

-

5. Digitize Post‑Production Procedures

After the print is done, go digital. Use software to plan your sanding, finishing, and assembly steps. Add a step‑by‑step flow that automatically sends you workflow cues and time estimates—a real “digital factory floor.” Anything that reduces manual error is a win.

In short, remember that additive manufacturing is a creative engine, not a perf. Once you get the balance between bold experimentation and solid engineering, you’ll find yourself producing results that are as reliable as they are innovative. Happy printing!

1. Utilize the freedom

Why 3D Printing Is a Game‑Changer

Traditional manufacturing—think injection molding or CNC—has a handful of rules that can feel like a set of strict dress codes. With injection molding, you need uniform wall thickness and smoothly radiused corners, otherwise the part won’t fill properly. CNC, on the flip side, struggles with deeply nested designs; its tools can’t quite reach the center of those hollow mountain‑high internal channels.

Enter Additive Manufacturing

3D printing throws that rule set out the window. It builds objects layer by layer, which means you can slice through almost anything. Need a maze‑like lattice or a mid‑build insert that’s tucked right where it fits? No problem. Want an internal channel that winds like a corkscrew? No sweat. The only limit is your imagination.

Freedom to Go Wild

- Design parts with labyrinthine structures that would trip up a traditional mold.

- Incorporate smart inserts that snap into place during the print.

- Create intricate internal routing for piping or wiring without the need for extensive machining.

In short, 3D printing lets you dream big and wire‑power your ideas straight into reality—something older methods simply can’t match.

2. Don’t fear parallelization

Why Teaming Up Multi‑3D Printers Is the Real Game‑Changer

Ever dreamt of printing a whole gadget in a single swoop, without the dreaded post‑print cleanup? 3D printers can do just that – one run, one part, zero extra fuss. But for the big league with lots of orders, you’ll need more than a single machine.

Enter “Parallelization” – The Batch‑Printing Boost

- Speed off the charts: Throw a dozen printers at a task and watch the output skyrocket.

- Cost efficiency: Though buying more printers feels like a wallet breath‑take, the long‑term savings are worth it.

- Ridiculously low waste: Studies show a 90% drop in material wastage when using parallel setups.

- One‑stop fab: Consolidate all fabrication steps—no more piling up joists or retooling.

- Per‑board miracles: You can produce complex boards in one go, leaving no room for human error.

So, Why Should You Juggle Multiple Printers?

Picture this: You’re finishing a batch of prototypes, the printers finish in harmony, and you have pristine parts ready to ship. No assembly lines, no rework, and a huge battery of raw or wasted material turned into ready‑to‑sell goods.

Bottom Line

Investing in a printer squad may seem like a splurge, but when you factor in time, cost savings, and a big reduction in waste, it turns out to be the smartest move. If you’re making things regularly, think of parallel print‑magic as your secret sauce for sanity and profitability.

3. Pay special attention to the deposition time

Cracking the 3D Print Scheduling Code

Hey designers, let’s keep things skin‑deep and simple.

Why Skip the Rehash?

When you use a 3D printer, you get to dodge those tedious “redo this from scratch” loops. Innovation feels fast – until you realize timing is a thing.

What Makes Deposition Time Tick?

- How many pieces you’re printing – more parts = more feed‑rate crunch.

- Total raw material mass – bulkier builds take longer to pour.

- Build size & weight – they’re the quick clues you need.

Get the Numbers Right

Instead of guessing, pull up a test coupon – a tiny silicon slice. Paint it up, run the printer, and you’ll see exactly how long the whole job will take. Trust us, it gives you the same precision without the maze‑like trial and error.

Bottom Line

Know your parts, weight, and a handy coupon, and you’ll command your 3D printer with the confidence of a seasoned builder.

4. Trust in data-based scheduling

Mastering 3D Prints with a Single, Mighty Command Hub

Imagine having one command center that watches over every print head, filament spool, and finishing station. That sweet spot lets you collect deposition data right as the plastic puffes out the shape it’s supposed to.

Why data‑driven scheduling matters

- Every product variant has a different clock: custom parts may need longer printing, others might jump straight into assembly.

- With a single source of truth, you can measure how long each job really takes – not just guess it.

- That real‑time timing then feeds back into your production calendar, letting you shuffle jobs for maximum efficiency.

It’s like having a conductor for a plastic orchestra: you know exactly when the violin (the print queue) should start, how long the cello (post‑processing) needs, and when the drums (assembly line) will kick in. By tuning that schedule with the data you gather, you turn a chaotic jam into a perfectly timed performance. And let’s face it – fewer surprises on the floor means happier workers and fewer frantic last‑minute sprint prints.

Bottom line

Centralizing your 3D printing assets gives you the power to measure, refine, and automate your production flow. The result? Faster builds, less beat‑down, and a smoother, more predictable workflow for every product version.

5. Digitize post-production procedures

Post-Production Pain? Let Automation Take the Load!

Even with all the smarts in today’s 3D printers, most companies still wrestle with the manual grind of post‑production tasks. Assembly and plating are like the never‑ending cliffhangers that drag out the finish line.

That’s where automation steps in. No more eye‑balling for real‑time supervision, no more manual juggling of screws and plates. Think of it as giving your production line a brain that never needs coffee breaks.

- Speed: Automation slashes the time your parts spend on the assembly line.

- Cost: Fewer labor hours mean tighter budgets and fewer surprise overtime charges.

- Peace of mind: You get to focus on design and innovation instead of chasing deadlines.

So why keep shuffling parts around when a smart system can smooth out the bottleneck? Let automation be the unsung hero that keeps your production line humming and your costs down.

Endnote

How to Keep Ahead in the 3D Printing Revolution

3D printing is no longer just a neat side hobby—it’s breaking out like a rocket every single day. The future promises smoother workflows and fewer headaches, but waiting around is a waste of time.

Got Tips? Here’s How to Plug Them In…

- Streamline Your Workflow – Trim the steps that slow you down. Think of it as chopping the “kinks” from the process.

- Cut Costs on the Fly – Use smarter materials, re‑use prints, and tweak settings to keep your bank account happy.

- Upgrade Your Skills now – Pick up that new software trick or piece of hardware. The sooner you get in, the faster you’ll win.

Want to feel like a printing pro without the grind? Use these pointers, watch your costs shrink, and keep your production humming perfectly. The future of 3D printing is yours—grab it before everyone else does!